Solutions for the protection and monitoring of industrial machines

In today’s industrial world, unexpected downtime poses a serious threat to productivity and efficiency, which is why businesses are continually looking for innovative strategies to optimize their operations, minimize downtime and maximize productivity. production efficiency.

The need for efficient and reliable machines is of fundamental importance, especially when dealing with large machines, such as turbines, reciprocating and centrifugal compressors, generators, gearboxes and any other machine critical for the operation and safety of the plants.

With over 30 years of industry experience, we offer innovative solutions for optimal maintenance planning, which help companies achieve optimal performance and major productivity improvements.

How do we do it?

Thanks to our team of experts, we are able to provide tailor-made solutions for integrated monitoring systems that identify machine problems before they appear. This approach increases the availability of the machines, allowing precise and timely interventions and reducing downtime to a minimum.

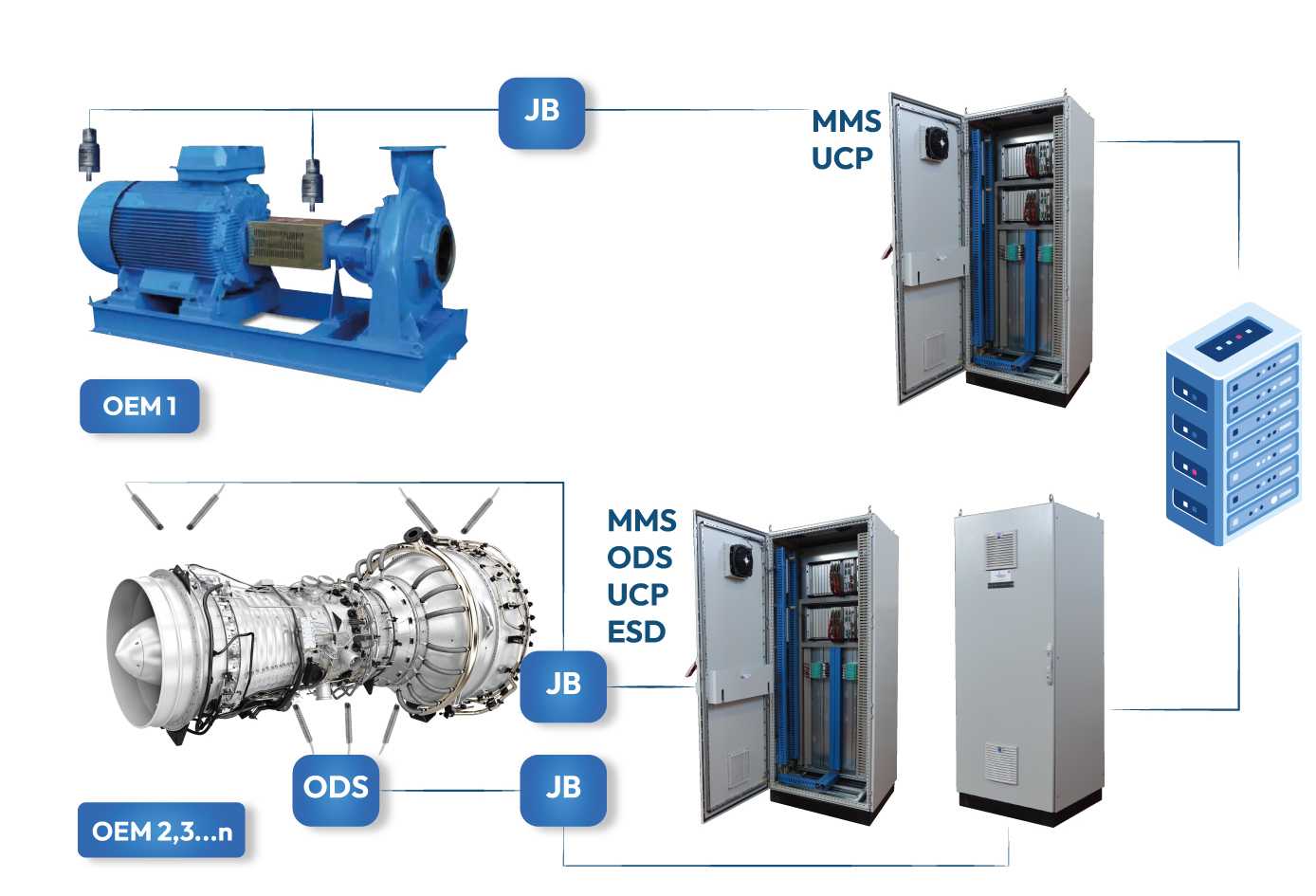

MMS and CMS turnkey solutions

We support our customers by providing customized solutions for the protection and monitoring of rotating and reciprocating machines, critical or semi-critical for the plant, on new installations or retrofits of existing assets.

We provide complete support, from the study of the sensors to be installed to the engineering of the control panels, up to the management of data towards software for condition monitoring or integration with third-party systems.

From the very early stages of consultancy and design, we select the most suitable technologies and brands to satisfy the requirements and project specifications, guaranteeing the best technical-economic performance of our customers.

Our turnkey projects include applications for:

- VMS | Vibration monitoring system;

- ODS | Overspeed detection system;

- UCP | Unit control panel;

- AS | Antisurge system;

- Online lubricating oil monitoring system.

Innovative system for monitoring lubricating oil

Our online analyzer for lubricating oil analysis is a new technology that today allows us to automate and monitor in real time the critical parameters of lubricating oil that are traditionally acquired manually.

Now finally data such as particle count (ISO 4408, NAS 1638), metal particulates, viscosity, water saturation and oil degradation can be acquired in real time and compared with other existing machine parameters (vibration and temperature) for a higher level of machine monitoring and diagnostics.

The system is easily installed externally to the machine, without making mechanical changes to the machine itself and through the use of specific sensors, it is able to send data in real time to the cloud allowing the customer to connect remotely or to third-party systems already existing in plant.

OUR SUPPORT

- Engineering and field installation;

- Commissioning and Start-up;

- Operator training;

- Diagnostic services;

- On-site assistance for connecting to existing third-party systems.